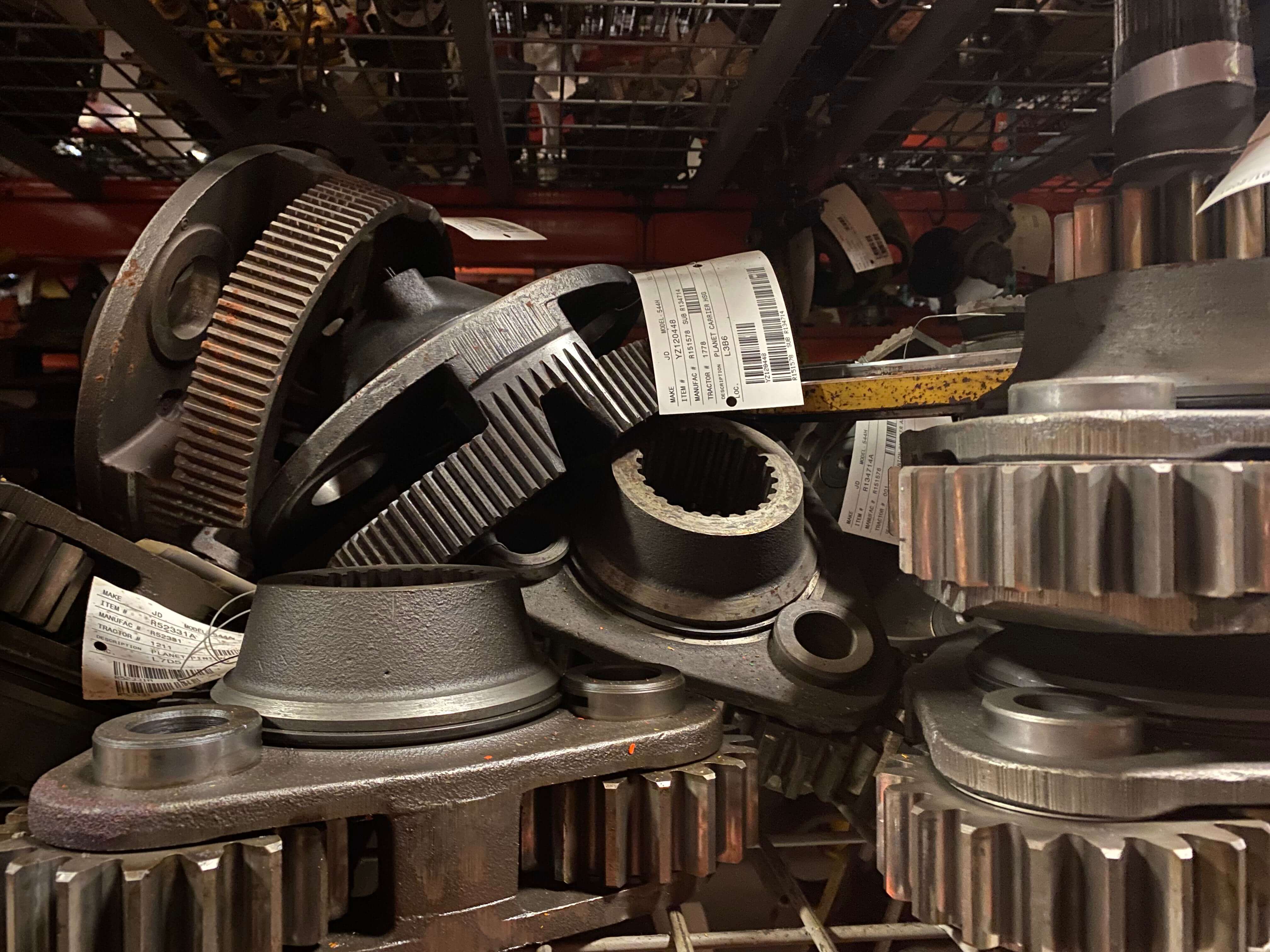

Discover a Vast Range of Aftermarket Construction Parts for Optimum Performance and Cost Savings

Wiki Article

Increase Performance With Aftermarket Parts: a Guide for Heavy Equipment Owners

Advantages of Aftermarket Components

Proprietors of hefty machinery can delight in various benefits by opting for aftermarket parts over initial equipment supplier (OEM) parts. Aftermarket components are commonly more budget friendly than OEM parts, allowing equipment owners to decrease maintenance and repair work costs without compromising on quality.Considering that aftermarket manufacturers specialize in generating certain parts, machinery proprietors have accessibility to a wider variety of choices to suit their needs. Aftermarket parts are understood for their quality and dependability, with many meeting or going beyond OEM standards.

Finally, picking aftermarket parts can additionally lead to faster repair work and reduced downtime. With much easier availability and fast shipping alternatives, equipment owners can obtain their equipment up and running once more swiftly, lessening interruptions to their procedures.

Picking the Right Aftermarket Components

When taking into consideration aftermarket parts for heavy equipment, it is necessary to focus on compatibility and quality to guarantee ideal efficiency and longevity of the equipment. Picking the appropriate aftermarket parts can be an important choice for heavy equipment proprietors as it directly affects the performance and reliability of their devices.

Secondly, quality ought to never ever be endangered when selecting aftermarket parts (aftermarket construction parts). Choosing for high-quality components makes certain sturdiness, reliability, and overall performance of the machinery. It is recommended to source aftermarket parts from trusted suppliers or vendors recognized for their top quality criteria

Furthermore, taking into consideration variables such as warranties, customer testimonials, and compatibility with existing systems can even more aid in making the best choice. By focusing on compatibility and high quality when choosing aftermarket components, hefty equipment proprietors can boost the efficiency and durability of their equipment.

Setup and Maintenance Tips

For reliable operation and durability of heavy equipment, appropriate setup and normal maintenance are vital. When installing aftermarket components, guarantee that you carefully follow the maker's directions to assure optimal performance. It is important to make use of the correct official site tools and strategies to avoid any kind of damages during the setup process. Regular upkeep is crucial to maintain your machinery running efficiently. Create an upkeep timetable that includes tasks such as examining liquid levels, inspecting for deterioration, and cleansing elements (aftermarket construction parts). Without delay attend to any kind of issues that arise to stop additional damage and pricey fixings. In addition, think about buying training for your upkeep staff to ensure they have the essential abilities to identify and attend to potential troubles. By focusing on installation and upkeep procedures, you can optimize the performance and lifespan of your heavy machinery, ultimately saving money and time in the future.

Cost-Effectiveness of Aftermarket Parts

Appropriate installation and normal upkeep are fundamental facets for heavy machinery proprietors intending to examine the cost-effectiveness of aftermarket components for their equipment. While initial tools producer (OEM) parts are understood for their quality, aftermarket components offer a more economical service without jeopardizing performance. By meticulously reviewing the quality and compatibility of aftermarket components with their machinery, owners can strike a balance in between cost-effectiveness and efficiency, inevitably optimizing the efficiency and longevity of their heavy devices.Optimizing Effectiveness With Aftermarket Upgrades

To enhance functional performance and efficiency, hefty equipment proprietors can properly take full advantage of effectiveness with critical use of aftermarket upgrades. Aftermarket upgrades provide the possibility to tailor hefty machinery to details operational demands, resulting in boosted capability and output. Upgrading elements such as engines, transmissions, hydraulic systems, and tracks can significantly improve the general effectiveness of the equipment.

On a regular basis evaluating the performance of heavy equipment and determining locations read the full info here where aftermarket upgrades can be helpful is essential for maximizing performance. By buying high quality aftermarket parts and upgrades, equipment proprietors can achieve greater degrees of effectiveness, eventually resulting in cost savings and improved operational outcomes.

Conclusion

Finally, aftermarket parts provide various benefits for heavy machinery proprietors, consisting of cost-effectiveness, enhanced performance, and customization alternatives. By choosing the right aftermarket components, following appropriate installation and upkeep procedures, and optimizing upgrades, hefty equipment owners can boost their equipment's performance and longevity. Spending in aftermarket parts can ultimately cause improved Going Here performance and minimized downtime, making it a beneficial factor to consider for owners looking to optimize their machinery operations.Proprietors of hefty equipment can appreciate many benefits by choosing for aftermarket components over original equipment producer (OEM) parts. Aftermarket parts are normally more cost effective than OEM parts, permitting equipment owners to decrease maintenance and repair work expenses without jeopardizing on top quality. By very carefully reviewing the top quality and compatibility of aftermarket parts with their equipment, owners can strike a balance in between cost-effectiveness and performance, eventually taking full advantage of the performance and longevity of their hefty tools.

In verdict, aftermarket parts supply many advantages for heavy machinery owners, including cost-effectiveness, enhanced performance, and customization options. By choosing the best aftermarket parts, complying with appropriate installation and maintenance treatments, and taking full advantage of upgrades, heavy equipment owners can boost their equipment's performance and long life.

Report this wiki page